Sheet metal stamping is a process that is done chiefly through the cold-forming process. You might be wondering what it is and how it is applied.

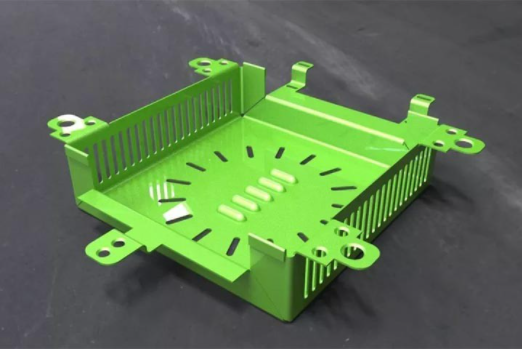

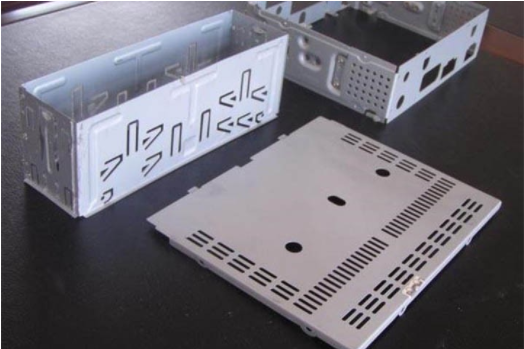

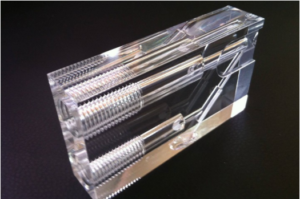

Well, sheet metal stamping is the process where sheets of metal are turned into useful parts or components. First, metal is designed into the desired shape using a stamping tool commonly known as a die. Three components make the sheet metal stamping process possible; the sheet metal, die, and pressing machine.

There are various steps followed during metal press stamping. They include:

Forming- This is the transformation of metal into another shape by the use of force.

Blanking- The process of cutting out the desired shape by stamping. This results in a piece called a blank.

Drawing- This is where vessels or deep depressions are formed on the blank. Again, this process might be complex, depending on the design.

Piercing- Desired holes are made on the blank.

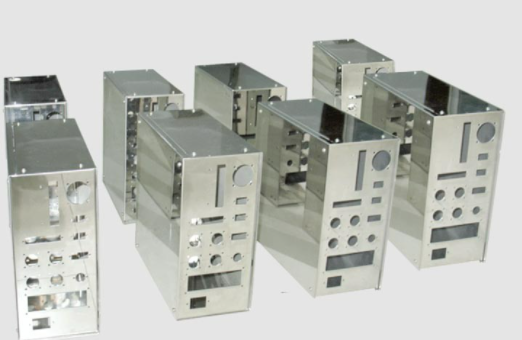

The list of companies using components created through sheet metal stamping is endless. This is because parts produced through metal press stamping are heavy-duty, superior, and resilient. To end up with high-caliber precision parts, you need to look for a company that offers the best service in sheet metal stamping. RM Mold, an ISO2768:2015-registered company, has been manufacturing precision parts over the years, so associate with us today for the best deals on precise parts.

- Part Size up to 3M.

- Fast Build Times- Small quantities can be shipped in 5~7days.

- Part Thickness: Up to 6mm.